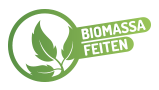

Covestro is moving forward with the implementation of a unique process for producing the important chemical aniline entirely based on plant biomass instead of petroleum for the first time. At its Leverkusen site, the plastics manufacturer has now put a special pilot plant into operation for this purpose. Initially, large quantities of bio-based aniline will be produced there, so that the new technology can be further developed for production and transferred to an industrial scale. In the plastics industry, aniline is used to produce MDI, among other things. This in turn is used for insulating foam, for example, which saves energy in buildings and reduces the CO2 footprint. Covestro believes it will contribute to the promotion of the Circular Economy, which the company is aiming to become fully aligned with.

“Among other things, aniline is a key raw material for foams used to insulate buildings and refrigerators,” explained Dreier, on the significance of the base chemical. “Until now, aniline has been produced from fossil raw materials such as petroleum, which releases CO2 and fuels climate change. With our new process, we are contributing to building up a circular, bio-based economy, and I am very proud that we have now succeeded in making the jump to the next technological level.”

Covestro developed the process together with partners in the scientific community. Compared to conventional technology, the process leads to a greatly improved CO2 footprint of aniline. Covestro has made a seven-digit investment in the pilot plant at the Chempark Leverkusen.

Use of biotechnology

The project also clearly showcases the potential contribution of the industrial (“white”) biotechnology to plastics production: in the new process, a customized microorganism helps convert an industrial sugar extracted from plants into an intermediate product through fermentation. This takes place under milder and thus more environmentally compatible conditions than in conventional processes. In a second step, chemical catalysis of the intermediate product then creates the aniline with one hundred percent plant-based carbon.

The research on bio-based aniline will also continue to be funded by the German government. The German Ministry for Food and Agriculture is funding a follow-up project (Bio4PURDemo) from Covestro and partners, which started in March 2022 and runs until 2025.

The RWTH Aachen with the CAT Catalytic Center and the University of Stuttgart, as well as the technology transfer initiative located there, are also participating in the project.

Around six million tons of aniline are currently produced worldwide, with the volume growing by approximately three to five percent per year on average. With a production capacity of more than one million tons per year, Covestro is one of the leading aniline producers.

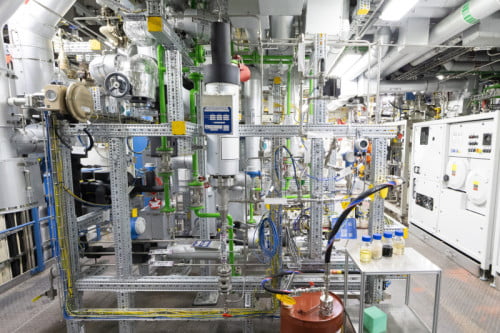

Pilot plant for bio-based aniline Leverkusen

Source: Covestro